Signatone

Showing all 8 results

-

Signatone Wavelink WL350 Probe Station System

The Signatone WaveLink WL-350-LE is a 300mm Semi-Automatic Probe System with a Local Enclosure for Reliable and Accurate RF applications with 2 & 4 port setup, DC, CV/IV, Pulsed –IV Test Measurements. The WL-350-LE is available in multiple and flexible configurations including a variety of Chuck options, DC/RF/High Power Positioners, Computer Aided Probes, Microscopes and Camera’s.

- Travel Range: 300mm

- Programmable X, Y, Z and Theta Chuck Stages

- Temperature Range: -60 °C to +300 °C

- Complete range of MicroPositioners

- Low Current Analysis

- HF & RF Microwave Probing

- Millimeter Wave Probing

- Thermal Characterization

-

Signatone Wavelink WL170 THz Probe Station System

The Signatone WL-170-THZ 200 mm Manual Probe System is an Industry proven Probe System designed for reliable and accurate test of mmW, THz, and Impedance Tuner applications. The WL-170-THZ is designed for a wide variety of banded, differential or broadband frequency Extenders and Automated Impedance Tuners with seamless integration of Extenders/Tuners provides a maximum of measurement dynamics. It is available in multiple configurations including a variety of chuck options, DC/RF/mmW Micro Positioners, Microscopes, Camera’s, PCB holders, and optional instrumentation racks, Vibration Isolation tables, and Thermal Chuck.

- X, Y Chuck Travel Range: 200mm

- DC To THz Probe Head Selection

- Complete range of MicroPositioners

- Frequency Extenders and Tuner Compatability

- HF & RF Microwave Probing

- Millimeter Wave Probing

- CV/IV Measurements & Failure Analysis

-

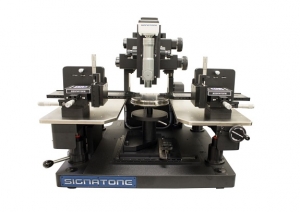

Signatone Checkmate Probe Station System

The Checkmate CM210 has manual control of both wafer and microscope stages and is pre-wired for easy in-the-field upgrade to motorized control. The CM220 has joystick controlled motorized movement of both the microscope and wafer stage. The CM230 has a joystick unit with precision dials to control both the microscope and wafer stages.

The Signatone CheckMate is an ultra-stable 200mm / 300mm analytical probe station with coarse and fine wafer stage movement to provide fast wafer movement as well as submicron resolution. The CheckMate series of analytical probe stations reflects a very simple philosophy of design – make it strong, make it stable, make it accurate and above all, make it easy to use.

- 10″ Cross-Roller Bearings for Smooth, Stable Operation

- Leadscrew driven contact/separate control with hard “Downstop” for Repeatability

- Nickel Steel or Aluminium Platens

- 2″ Platen range with lock

- 4 Point Platen support and lift

- Pneumatic Chuck Contact/Separate switch

-

Signatone CM460 SemiAutomatic Probe Station System

The CM460 is a 6″ Semi-Automatic Probe Station, rich in features and capability, that offer a human engineered interface to make operation easy and intuitive. CM460 Systems can be configured for a variety of applications including microwave probing, low current (femtoamp) probing, thermal probing, design/debug, failure analysis, product engineering and many other probing applications.

Systems incorporate a proprietary linear induction motor and an optical feedback positioning system to drive and control the wafer stage. This marriage of sophisticated technologies has given Signatone a leading edge in performance, reliability and accuracy. All systems include automated wafer stepping controlled via the Signatone Solutions Windows software and motorized theta with a quick two-point align feature. Options include programmable motorized microscope movement, auto focus, computer aided probes, on screen video, a unique joystick/thumbwheel control unit, and many other powerful features.

- 150mm Linear Motor Drive

- 2 Point Software Alignment

- Software Z Control

- 2″ and 6″ Manual/ Programmable/Hybrid Microscope

- Optional 4″ Microscope lift

-

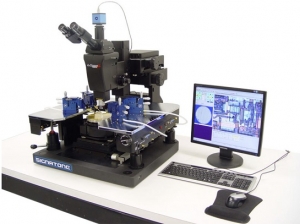

Signatone S1160 Probe Station System

The Signatone S-1160 probe station is used universally to achieve precise measurement results incorporating proven technology for I-V/C-V measurements. The S-1160 is equipped with ergonomically positioned controls and is available with a significant variety of options giving users greater application flexibility.

The S-1160 optimizes user test time and accommodates both stereozoom and high magnification microscopes and CCD camera mounting. At Signatone we know that X-Y-Z accuracy is the name of the game, whether you are moving the microscope stage or the DUT stage, the S-1160’s smooth X-Y-Z motion control is unrivaled. The singular, steel platen provides a stable platform for up to 12 Signatone micropositioners. The platen quick lift handle is ergonomically placed for quick up-down motion of the platen moving your probe tips out of contact on your DUT; this allows for quick X-Y positioning of the DUT stage and DUT loading and unloading. The platen fine adjustment knob gives users 5 micron resolution for fine Z adjustments for all of their probes simultaneously and allows users the height adjustments that they need for a variety of device sizes and shapes up to 1.35 inches in thickness.

- Triocular Stereo Zoom or High Magnification Microscope

- Supports DC, Coax, Triax Probe connection

- Large Steel Platen

- Linear Platen lift Lever

- Chuck Rotation Lever

- Vacuum Chuck

- Vibration Damping

-

Signatone H150 Probe Station System

The Signatone H-100 Series Probe Stations include a three inch square device / substrate chuck and are primarily designed for probing thick film devices such as ceramic substrates, printed circuit boards and hybrid circuits. The H-150 system, however, can be equipped with a four inch diameter wafer chuck for probing wafers up to four inches in diameter. H-100 Series Probe Stations are available in three versions: H-100, H-120 and H-150.

The modular design provides a wide number of options to suit a broad range of needs. All models include an aluminum base casting, a device stage with four inches of X-Y travel, a linear motion platen that can be raised and lowered using either a crank or a lever, and a microscope tower for mounting Stereozoom optics in a fixed position. A 4″ x 4″ microscope stage is optional. The platen will accept up to six magnetic based Micropositioners and a probe card adapter for use with probe cards. Micropositioner electrical connections are made through six pin jacks that correspond to color coded banana plugs.

- 4″ x 4″ Stage Movement

- Positioning Samples up tp 4″ Square

- Fine Platen lift allows accurate set-up Positioning of Wafers, Ceramic Substrates or Deep Cavity Packages

- Coarse Platen lift lever raises the platen 3/8″ for easy sample repositioning or changing

-

Signatone QuadPro II Resistivity System

The Signatone QuadProII Automatic includes a computer, stepper controller, and base station with either a 200 or 300mm diameter isolated chuck. The software automatically defines the points for automated testing and mapping of the test sample. The user enters the sample size, sample shape, edge exclusion, and choice of 5, 9, 25, 49 or 121 test points. The software automatically defines the best probe position for creating a uniform contour map. Users may also define their own custom positioning map with up to 14,000 test points. The user map may be defined by moving to position and recording the location or keying X-Y positions into an X-Y position table.

- Measures V/I, Sheet Resistance, Resistivity or Thickness

- Reports Average, Standard Deviation, Minimum, Maximum and 1Sigma for the data set

- Temperature Coefficient of Resistance (TCR) measurements integrated with automated temperature chuck and Source Meter.

- Automated 2D Color Contour mapping, 3D and Cross section mapping

- Employs the Dual Configuration Testing method for improved accuracy and repeatability

- Tests samples 10mm to 300mm

- P/N Typing

- Comparative Mapping

-

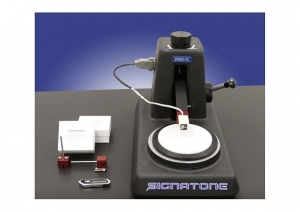

Signatone Model Pro4 Four Point Resistivity System

The Signatone Pro4 provides simple answers to sheet and bulk resistivity measurements. Since 1968, Lucas-Signatone has offered an inline four point probing solution. To make the measurements, the user lowers the four-point probe head onto sample then selects the test button in the software. The computer automatically controls the instrument and steps through a number of current settings to find the ideal current for accurate readings.

A V/I measurement is taken and recorded. The system uses the Dual Configuration test method of ASTM Standard F84-99 to compensate for errors in probe spacing and errors caused by proximity to the edge of the conducting layer. NIST traceable calibration standards are available for purchase with the system. Proper use of the standards and the calibration procedure insures the specified system accuracy of better than 1%. The standard range of the system is 1 miliohm up to 800K ohms-per-square.

- 4 Point Probe Head

- Three spacings available are: 0.040, 0.050 and 0.0625 inches.

- Three pressures available are 45, 85, and 180 grams

- Tips are made of Tungsten Carbide or Osmium and a choice of .0016, .005, .010 inches radius